Contact us

1. Energy saving. Radiator flash welding machine for tw […]

1. Energy saving. Radiator flash welding machine for two 125KVA resistance welding transformers for power, pneumatic compression, upsetting, no hydraulic station. Compared to other welding machines that use two 315KVA single-phase AC welding transformers and two 18KVA hydraulic station welders, the UN-250AB welder can save up to 78℅.

2. Low power grid requirements. It can only meet the grid of 250KVA.

3. High welding precision. Using programmable controller PLC and imported stepping motor to control the flashing process, the burning and burning speed can be set accurately; welding current is controlled by microcomputer welding controller. It can be controlled within ±0.2mm, which is convenient for subsequent welding parts.

4. Automatic centering function. Make sure that the two ends of the pipe are the same between the two ends to ensure the same amount of combustion at both ends.

5. High welding efficiency. With the time of workpiece pressure and force cylinder, the reaction speed is significantly faster than that of hydraulic cylinder.

6. Easy to operate and maintain. No hydraulic station, product debugging points, less fault points, no oil spills, etc.

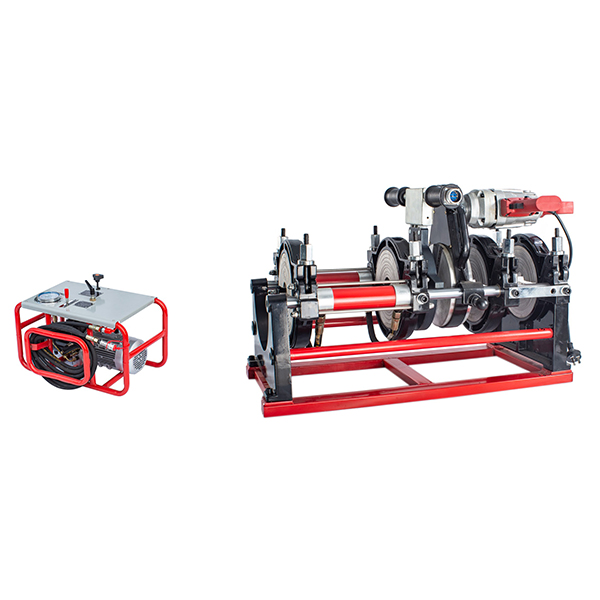

Zhejiang Cheng hong machinery co., LTD is a professional engaged in PE, HDPE, PPR thermoplastic piping engineering machinery manufacturers, with advanced technology, practical function, the product through the CE certification, by country, customers at home and abroad.Within the scope of zhejiang province is the largest of the welding.

Specializing in the production of supply automatic docking hot melt welding machine, semi-automatic docking hot melt welding machine (hydraulic semi-automatic and manual), large diameter plastic pipe socket welding machine, PPR hot melt. The products are sold well all over the country more than 30 provinces, autonomous regions, and exported to the Middle East, eastern Europe, southeast Asia, central Asia and other African countries.

The company always adheres to the goal of survival by quality, management of price market, facing new and old customers, and serving the public. Leading technology, honesty and trustworthiness, quality improvement, customer first, let the most advanced equipment, provide the best service, create better economic benefits for customers as the goal, and work with new and old customers to create brilliant! In 2011, based on the principles of honesty, goodness, mutual benefit, survival with quality stars, credit policy for development, market prices, management goals, and the needs of new and old customers, the products are exported all over the world.

Place of Origin: Zhejiang, China

Brand Name:Chenghong

Input Voltage: 220V--230V

Usage: Butt Welding

Certification: CE ISO

Color: Red or customised

OEM: OEM Acceptable

Type: Hydraulic

Applicable Materials: PE, HDPE, PP, PVDF, PPR, PB

Quick Links

Products

Contact Us