Contact us

As a general non-cutting forming processing equipment, […]

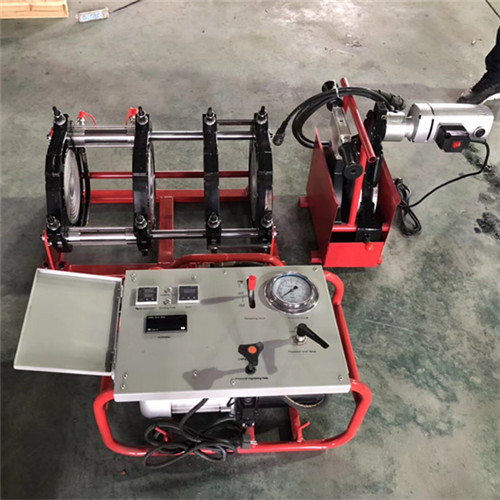

As a general non-cutting forming processing equipment, hydraulic press works based on the use of liquid pressure to transfer energy to complete various pressure processing.

Its work characteristics:

First, the power transmission is "flexible" transmission, which is not as complicated as the power transmission system of machining equipment. This driving principle avoids the situation of machine overload;

The second is that there is only a single linear driving force in the stretching process of the hydraulic press, and there is no "angled" driving force, which makes the processing system have a longer life span and a high workpiece yield.

The hydraulic press has three basic action modes: single action, double action, and triple action. In the single-action mode, the indenter (or sliding plate) is used as a moving part to move in one direction to complete the pressing process. There is no crimping device in this way of working. Single-action presses are mainly used in the forming of thin workpieces, suitable for coil and strip materials. The double-acting press has two moving parts: a slide plate (or punch) and a template. The working process is that the punch (or slide plate) stretches the punching material from top to bottom, and the template is used as a fixed pressure plate. After pressing and forming, the template can realize the function of ejecting the material. The pressure of the template can be adjusted according to the characteristics of the material and the hydraulic press of the workpiece. In the three-action press, the deep drawing slider and the blanking slider move from top to bottom, and the punching action is realized by the template. However, the template can also be used as a blank holder to achieve special molding operations. This type of press can also be used as a dual motor. Since the inner slide plate and the blank holder are connected, the forming pressure and blank holder force are combined into the total load of the entire system.

According to the frame structure, hydraulic presses can be divided into beam-column type, combined frame type, integral frame type, single arm type, etc. Hydraulic presses can be divided into ten types of manual hydraulic presses, forging hydraulic presses, stamping hydraulic presses, general-purpose hydraulic presses, correction, press-fitting hydraulic presses, laminating hydraulic presses, extrusion hydraulic presses, pressing hydraulic presses, packing briquetting hydraulic presses, and special hydraulic presses according to their functions.

Quick Links

Products

Contact Us