Contact us

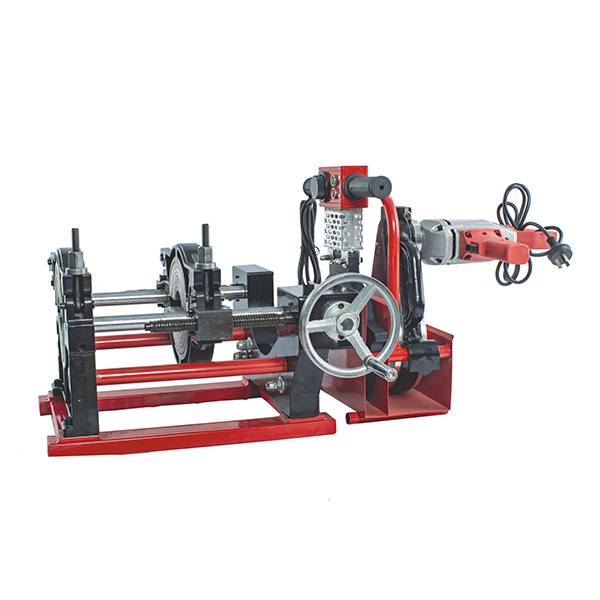

PE butt welding machine has won the recognition for its […]

PE butt welding machine has won the recognition for its work attitude of excellence and continuous improvement and innovation. Is there anything we need to pay attention to when using electric fusion welding machine? I believe that everyone has their own opinions on how to use the electric fusion welding machine.

The models and parameters of products produced by each manufacturer are different. Therefore, when choosing an electric welding machine, the latest automatic electric welding machine that supports both manual and barcode use should be selected. Thereby reducing the efficiency of use, causing unnecessary waste, and the price of the pe pipe electric fusion welding machine will also have an impact on the quality of work.

During construction, generally, when the power supply is within 50 meters from the welding machine, it is necessary to select the input cable of 2.5mm2, the electric fusion welding machine, and so on. The longer the distance, the greater the voltage of the cable used. When required, a generator must be selected to support the power supply at this time. There are strict requirements when using the electric fusion welding machine. It must be used by professionals and certified personnel. Non-professionals should not approach it, so as to avoid unnecessary danger to the operator.

From a technical point of view, the electric fusion welding machine belongs to the power supply range, which integrates power electronic technology, automatic control technology, automatic detection and automatic identification technology, computer hardware technology, software technology, display technology, barcode scanning technology and database technology. As a whole, it mainly provides constant welding voltage or welding current for welding, and detects and controls the welding process, so that the welding result can reach the best state. Features:

1. Automatic IC closed-loop design, when welding cannot meet the needs of welding conditions (such as voltage, current, temperature faults) according to the standard, it can automatically detect and judge various welding faults, and prompt the corresponding alarm code for the operator's reference. .

2. Connecting to a professional printer can instantly print out the actual welding parameters for archiving, which provides a reliable guarantee for mastering the real welding materials first-hand. Copy the data to the computer for printing through USB.

3. The pipe connection conversion plug adopts the latest patented product, which changes the traditional connection method and reduces the resistance value change caused by poor contact during connection, thereby avoiding the actual welding parameter caused by the resistance value change. deviation.

4. The ambient temperature automatic detection system can automatically perform welding compensation according to the detected ambient temperature and according to the requirements of the pipe fittings manufacturer.

Quick Links

Products

Contact Us